Valves

Intro

A valve is a mechanical device that control, regulates and direct the flow of fluid by opening, closing, or partially obstructing various passageways or basically it controls the flow and pressure of a fluid within a piping system. Valves are technically fittings, but are usually discussed as a separate category.

Valve uses:

Valves provide several functionality based on their design, size, working and other factors. Some of the functionalities valves can provide includes:

- Starting and stopping the flow of fluid based on the valve state(close or open)

- Regulating pressure and flow of fluid or gas within a piping system.

- Throttling flow rates within a piping system

- Controlling the direction of flow

- Providing safety through relieving pressure or vacuum in a piping system

You can contact Heera Traders, for further information’s.

Types of Valves:

| Ball Valve Ball valve is equipped with quick-acting 90-degree turn handles, these valves use a ball to control flow to provide easy on/off control. Generally accepted by operators to be faster and easier to operate than gate valves. |

| Butterfly Butterfly valve is quick-acting rotatory motion valve ideal for tight spaces. Butterfly valve bodies are offered in different configurations. |

| Check valve Check valve prevents backflow, these valves are typically self-activated allowing the valve automatically opens when fluid or gas passes through the valve in the intended direction and close should flow reverse. |

| Gate valve Gate valve is one of the most common valve type. It uses linear motion to start and stop the flow. These are typically not used for flow regulation. Instead, they are used in the fully open or closed positions. |

| Globe valve These valves are typically applied in modulating control operations. Globe valve are generally available in three types, Angle Body, Y-Pattern and T-Body (as show in figure). |

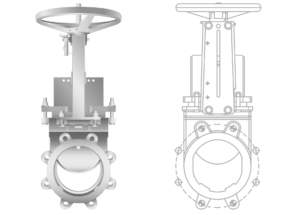

| Knife Gate Knife Gate are used for controlling flow of media containing solids. It consist of a thin gate controlled through linear action which can cut through materials and create a seal. Not suited for high-pressure implementations, these valves are ideal for use with grease, oils, paper pulp, slurry, wastewater and other fluids which might obstruct the operation of other valve types. |

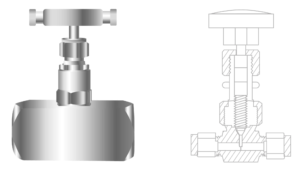

| Needle Needle Valve used in small diameter piping systems when fine, accurate flow control is needed. Needle valves get their name from the point on a conical disc used within. |

| Pinch Pinch Valve used for handling solid materials, slurries and liquids with suspended solids, pinch valves use a linear motion. Pinch Valves feature an internal sleeve to isolate the media. |

| Plug Plug Valve using a quick-acting quarter-turn valve handle, these valves control flow using tapered or cylindrical plugs. They provide some of the best ratings when tight shutoff is essential and are reliable in high-pressure or high-temperature environments. |

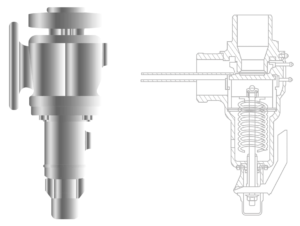

| Pressure Pressure Relief Valve used to help improve safety, these valves are spring-automated and will help to return a system to the desired pressure during over-pressure events. |

See More:

Choosing the right valve:

Choosing the right valve for your project might seem complex, however by starting with general characteristics such as valve design, size and actuation method you can limit you can limit your options to choose the best valve for your need. While valves might be a small part of your piping process or system in terms of space, they’re often a substantial portion of the design and build budget. They also have a significant impact on long-term costs and overall system performance.